Shape memory alloys in a nutshell

What are shape memory alloys?

Shape memory alloys (SMA) belong to the group of smart materials. They are produced in various forms - e.g. as thin wires, springs or sheets. Shape memory alloys are characterized by a special effect: they are soft and easily deformable when cold, yet they "remember" their original shape as soon as they are heated (e.g. by an electric current). When heated, the material becomes stiff and can generate high forces.

How does it work?

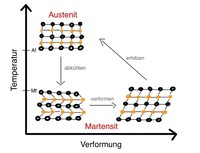

The shape memory effect is caused by a special structure of the crystal lattice: The alloy has two different crystal structures. In addition to the high-temperature phase (austenite), there is a low-temperature phase (martensite).

In its martensitic state, the material is soft and easily deformable. In austenitic state, on the other hand, it is stiff and tries to return to its original shape. The temperature required for phase transformation depends on the composition of the alloy. Nickel-titanium alloys are most commonly used. In addition to the temperature, the mechanical stress in the material also has a significant influence on phase transformation.

Where are shape memory alloys used?

Shape memory alloys are frequently used in actuators. They offer many advantages: Shape memory alloys are true athletes; they have the highest power density of all actuator materials. They are also lightweight, operate in a noise-less manner and are well-suited for miniaturization. Applications are becoming more and more numerous: pneumatic valves for automotive seat comfort, active optics in smartphone cameras or stents in medical technology are just a few examples.